Which structural device is best to reduce seismic demand?

We often get asked how do Tectonus seismic dampers compare to a Buckling Restraint Brace (BRB). In this article, we compare the Tectonus RSFJ self-centering seismic damper to a BRB. However, a more direct comparison can be made between Tectonus DMAX, a straight swap for a BRB in any braced frame system.

Before getting into the unique market factors, performance abilities, and quality of these seismic protection devices, let’s start with the basics.

What is a BRB?

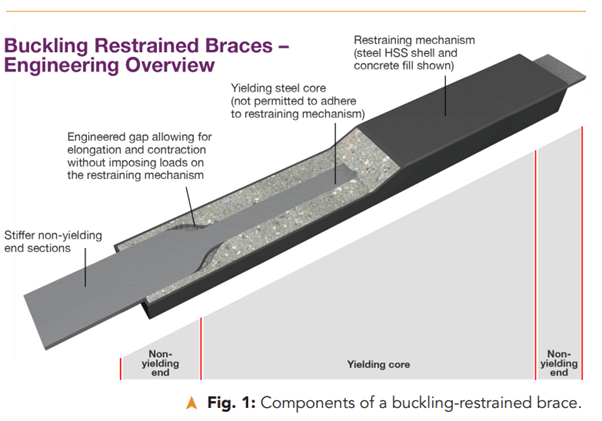

A BRB is a structural brace intended to yield when exposed to extreme forces such as an earthquake. They consist of a steel core encased in concrete. The thin steel plate can elongate and provides significant ductility in tension. Under compression loads, because it is thin, it will buckle and has no resistance. Therefore, the concrete casing provides this buckling restraint.

Image credit: AISC

Originally developed in Japan, the technology is widely available through North America, Italy, New Zealand and other earthquake prone regions.

What is the RSFJ?

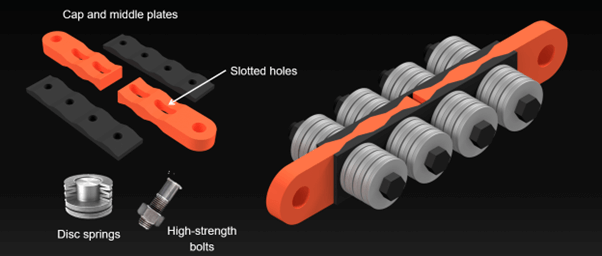

Tectonus developed the self centering seismic damper which is intended to dampen the force of an earthquake and then, fully self-centre itself. It is composed of ridged steel plates connected by steel rods and conical washers. The ridged plates clamped together provide the friction in tension or compression, and the conical washers effectively act as springs allowing the device to return to its original shape once the load comes off.

The technology is now widely used in New Zealand with initial projects delivered in Canada and in development in Japan and the USA.

Market Factors

BRBs are well known and manufactured by several different providers. Because they have been around so long, many engineers know how to design with them. In addition to this, they’re relatively inexpensive and have been adopted into codes in e.g. the USA. Tectonus RSFJ being a proprietary technology, and new to market, is much earlier in the adoption cycle.

| BRB | RSFJ |

| Known by many | New to market |

| Per unit cost is relatively lower | Per unit cost is relatively higher |

| Accepted as a standard solution in some markets like the US, alternate solution in others like NZ | Alternate solution |

| Patent expired so is available from many suppliers | Patent protected - one supplier |

Performance

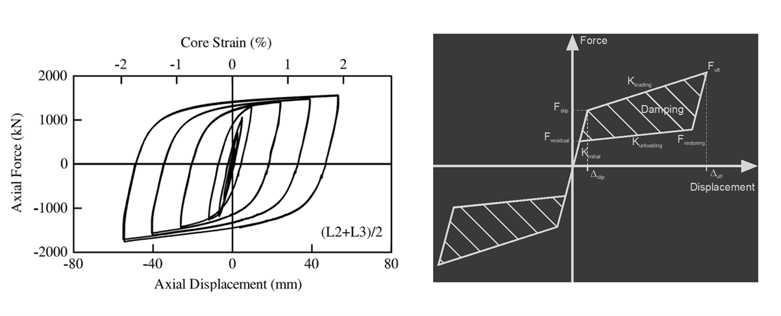

Tectonus RSFJ is unique amongst seismic devices for its ability to fully self-centre. Though it has less raw damping capacity, the Tectonus RSFJ affords other advantages to the structural designer such as a lower overstrength factor. Notably, the RSFJ deals with both earthquakes and aftershocks the same without any reduction in performance. To what extent the extra damping provided by a BRB to structures is actually useful, is still under research.

Typical hysteresis curves of BRB (left) and RSFJ (right).

Typical hysteresis curves of BRB (left) and RSFJ (right).

| BRB | RSFJ |

| Does not self-centre | Self-centres |

| Provides up to 50% damping | Provides up to 20% damping |

| Over-strength factor of 2 or more | Over-strength factor of 1.35 |

| Capacity can be very high | Large capacity results in large volume |

| Low inelastic stiffness resulting in high post-slip accelerations | High post-slip stiffness reducing accelerations during damping |

| Has strain hardening | Has a secondary fuse |

| Performance significantly reduces after main shock with lesser protection in after shocks | Performance remains constant through main shock and after shocks |

Maintenance & Repair

Both BRBs and Tectonus RSFJs are set and forget until an earthquake, at which point a BRB will most likely need to be replaced. An RSFJ on the other hand can be used repeatedly.

| BRB | RSFJ |

| Does not require maintenance | Does not require maintenance |

| Can’t be inspected since the yielding element is encased in concrete | Can be inspected following an event |

| Must be replaced after design level earthquake | Does not need to be repaired or replaced after design level earthquake |

| Potential buckling of core when out of sleeve | Buckling is prevented using Anti-Buckling Tube |

Quality Assurance

Knowing that the seismic device employed performs to specification is essential for structural designers. Uniquely, the Tectonus RSFJ can be fully performance tested to the design level earthquake. Meaning every unit is tested prior to shipping and comes with a testing certificate. Consequently, BRB’s cannot be fully production tested as they are designed to yield.

| BRB | RSFJ |

| Production testing not possible since it will be damaged | Each product is fully tested after production to the design level earthquake |

| High reliance on steel properties | QC guarantees performance to ±5% of specified performance |

| Can be fire protected | Can be fire protected |

Application

The RSFJ is inherently flexible as is the BRB. However there are some common differences.

| BRB | RSFJ |

| Commonly used in Buckling Restraint Braced Frames (BRBFs) | Can be used as a brace in frames – whether timber or steel |

| Can only be used in tension/compression braces | Can be used in tension only or tension/compression braces |

| Timber brace is not possible | The only resilient timber brace existing in the market |

RSFJ in a timber brace in the Hutt Valley Health Hub.

In Conclusion

The BRB is the stalwart of structural design in seismic areas. It is relatively cost effective, easy to design with, has high damping ability and can scale to accommodate large loads. That’s why for many structural engineering applications it’s the seismic device of choice.

Tectonus RSFJ is the new kid on the block. As adoption grows and volumes increase the technology cost will come down and it will get easier to design with it. It offers the structural designer a lot of flexibility across several applications. In a real earthquake its performance through main shocks and aftershocks is hard to beat.

Given the unique performance of the system, the RSFJ can be used as the single lateral load resisting system while the BRB is often used in parallel with another system (such as steel MRF or viscous dampers) to enhance the performance. The relatively higher over-strength factor of the BRB (as a result of unpredictable performance and difference in tension and compression performance) can be a limiting factor, especially in retrofit schemes. Post-slip stiffness of the RSFJ is adjustable while there is no post-yield stiffness for BRBs.

For a more direct replacement of a BRB in a braced frame system, please consider Tectonus DMAX which has the same damping capacity as a BRB but has a much lower overstrength factor (1.15). This creates a value engineering opportunity by reducing the design loads for adjacent members, connections and foundations.

If you’d like to learn more about how a Tectonus RSFJ seismic damper could benefit your building project, download our product brochure or get in touch.