MASS TIMBER CONNECTIONS

Designing mass timber lateral load resisting systems (LLRS) in seismic regions is challenging. As a result, most mass timber buildings use steel frames or concrete cores. Tectonus was founded by world-renowned experts in seismic design of mass timber LLRS. We have the experience, design skills and technology to help realize all-timber buildings.

Mass Timber Applications

.png?width=300&name=5e66f4b13cb7cea5655828cf_HVHH-brace%20(1).png)

Mass timber structures - seismic challenges

Mass timber buildings have the advantage of lower mass and reduced seismic forces. However mass timber LLRS does present some unique challenges:

- Lower ductility. Mass timber is less ductile than concrete and steel and the members are brittle.

- Connection detailing. Improperly designed or executed connections can result in reduced seismic performance.

- Failure modes. Mass timber fails differently. For example split beams, broken dowels.

- Sacrificial connections. Conventional timber connectors yield to provide ductility, losing their ability to withstand aftershocks.

Tectonus know-how and technology was developed specifically to address these challenges.

“Based on my 30 years' experience designing timber structures, I can see no better seismic solution for mass timber wall hold downs than Tectonus. Damping, ductility, and recentering in a compact package that is also simple to install on site.”

ROBERT MALCZYK

Principal, Timber Engineering

Cost Study

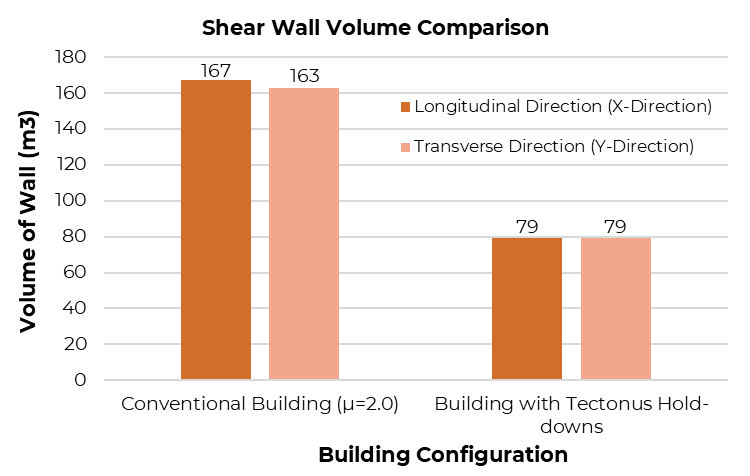

In this project Tectonus hold downs were compared to a conventional solution in a 3-storey residential apartment building in Wellington, New Zealand:

- 190% increase in ductility

- 47% reduction in shear wall volume

- 71% reduction in the number of fasteners

Tectonus hold downs paid for themselves in the savings from timber and fasteners alone - additional savings were realized in the foundations though these were not calculated.

How can we help?

Get in touch to ask a question or schedule a free consultation